Seedinspector and micro-computer tomography (CT)

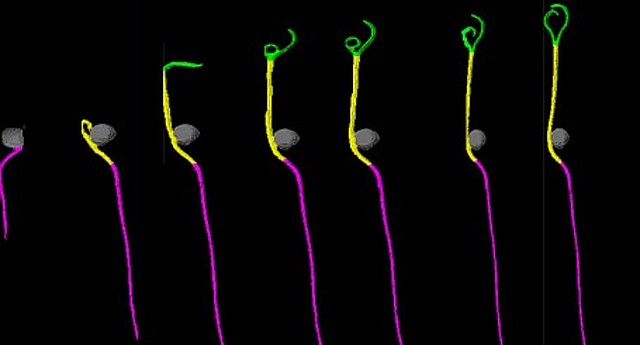

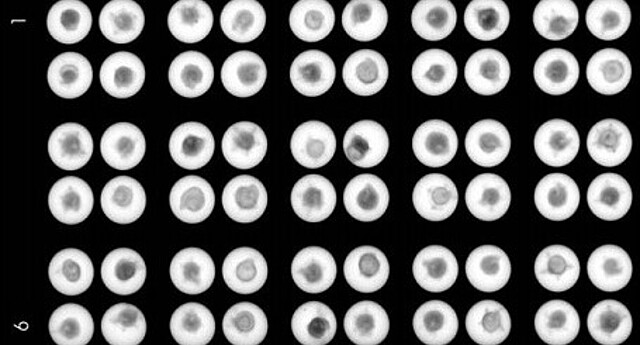

During the conditioning process, we look directly inside the seed. Using our own 3D micro-computer technology, we examine the tissues of the raw seeds. The CT results show which seeds are filled and have a well-developed embryo capable of germination. We use these results for the processing of our commercial seeds. It allows non-destructive selection of the seeds with the best seed quality.

The properties of the seeds are determined by the external conditions during growing. However, some characteristics are defined genetically. For this reason, we share our knowledge with our breeding partner Strube Research. In this way, we can also improve the quality of our seed through breeding.

CT fast track procedure: With the SeedInspector, a further development of the CT, we analyse the seed fully automatically. The lab robot supplies itself and examines the seed with a high throughput.